The target is value stream-oriented production that functions without waste and is the decisive basis for the company's competitiveness.

Lean Production

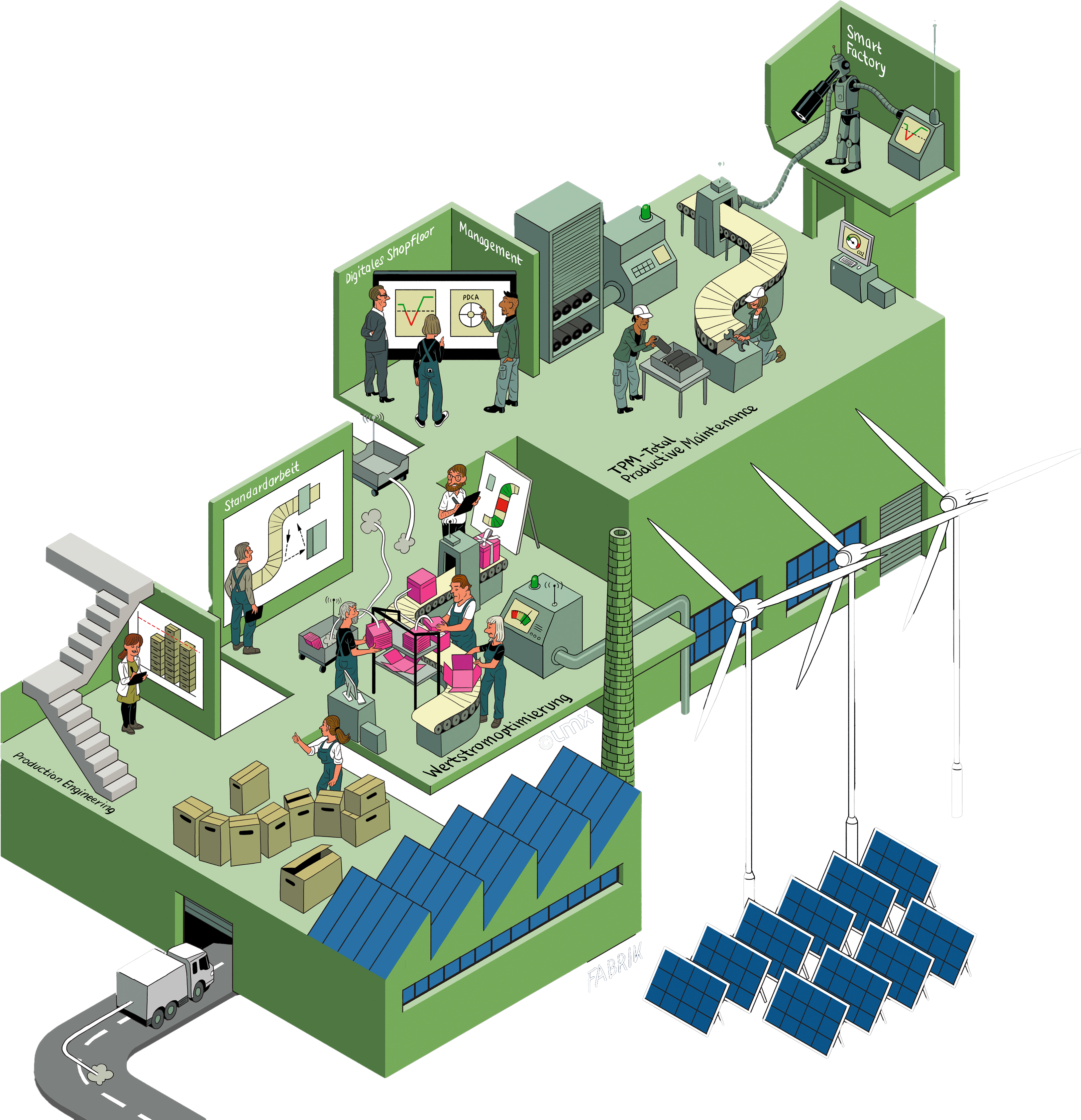

Following the example of major automotive manufacturers, numerous companies have designed precisely defined production systems with precisely coordinated process landscapes. The target is value stream-oriented production that functions without waste and is the decisive basis for the company's competitiveness.

The roll-out of lean production concepts across all departments and plants is a challenging task that can only be successful with the involvement of all employees from the relevant production areas. The LMX team has extensive expertise in supporting similar tasks in various nationally and internationally active companies.

Typical types of waste in production

- Overproduction

- Stocks

- Transportation

- Waiting time

- Error

- Work process (overfulfillment)

- Incorrect employee deployment

Typical results of lean production

- Increase in productivity

- Reduction of lead time

- Increase in delivery reliability

- Increase in quality

- Increase in throughput

- Increase in customer satisfaction

- Increase in employee satisfaction

Ralf Langmaack

Partner

Phone: +49 211 63 55 89 60

Fax: +49 211 63 55 89 69

Email: info@lmx.eu

Lean Management & Digitization 2025 at Ruhr-University Bochum

Our solutions

Value stream optimisation, line design

We analyse the process steps in the production line and derive improvement measures from them.

Goal: Flowing processes, low inventories and throughput times

Production Engineering

We create a preliminary design or simulation of the production line from cardboard boxes or similar before the machines and equipment are ordered.

Goal: Optimal and production-oriented process design

(Digital) Shopfloor Management

Shopfloor management is a management tool in production to make the current status of production transparent. It is visualised via team boards where the most relevant key figures are discussed regularly (usually daily).

Goal: effective cooperation in the team, fewer meetings, controlled CIP, PDCA

Standard work

This is about the efficient design of the workplace of the factory employees. Unnecessary paths and work steps are to be avoided.

Goal: Efficient and repeatable standard work processes, short distances

Material supply according to demand

The individual work stations are supplied with the required material as needed. Nowadays, this is also automated without a human driver (AGV - automated guided vehicle).

Goal: efficient and reliable material supply oriented to the customer's cycle.