Measurable increases in efficiency and productivity can also be achieved for product design processes using lean management methods if the levers are applied correctly

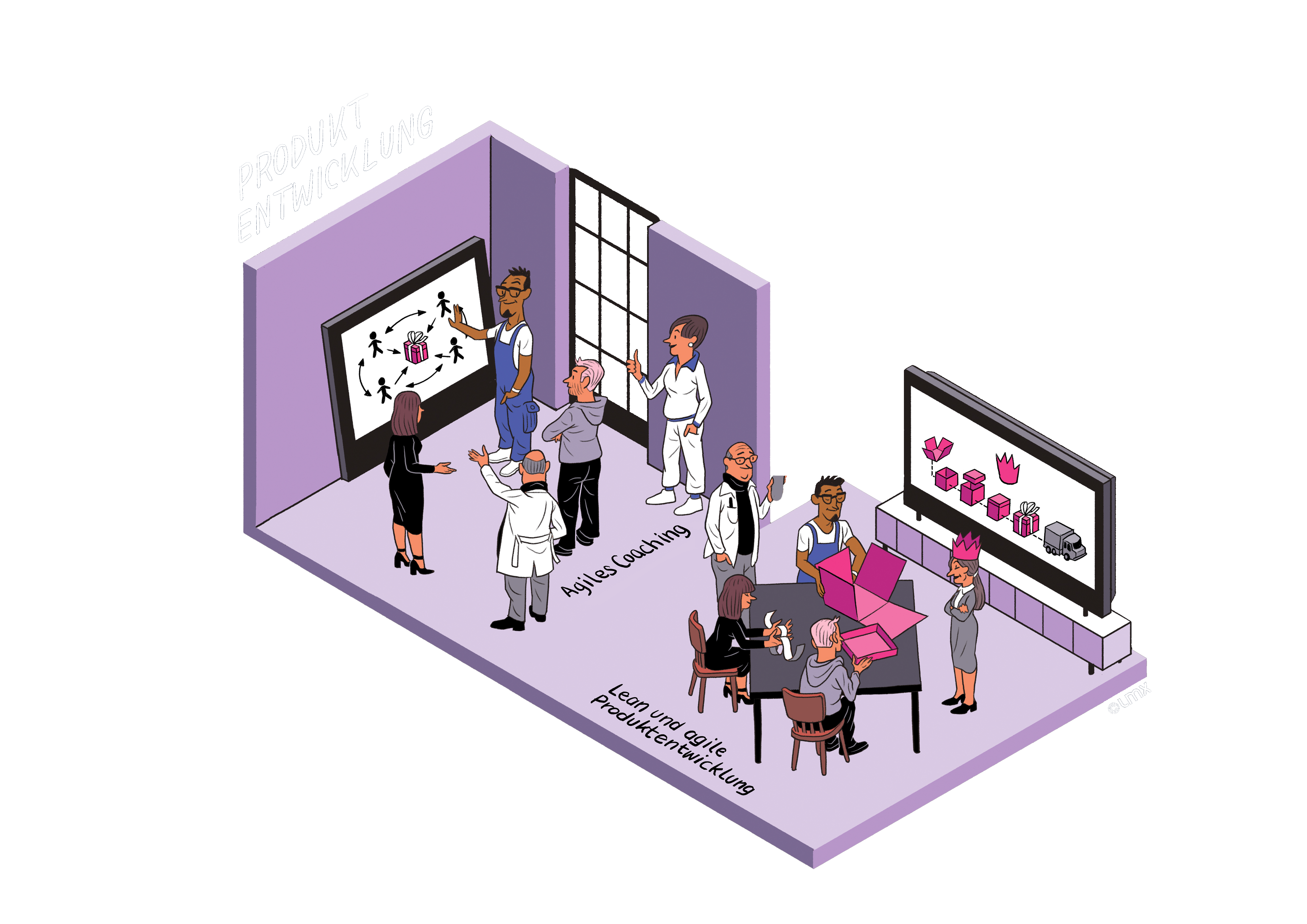

Lean Development

With its extensive expertise, LMX uses an innovative approach to optimize development areas through lean principles.

The key lever in Lean Development to improve business performance is the reduction of cycle time.

The implementation of Lean Development in a company follows a 3-step model based on the application of specific methodologies. The first step deals with the efficient self-organization of the development project members, e.g. with filing structures, work standards or problem solving techniques.

The second step focuses on improving the development process, e.g. through Obeya & Gemba control loops, visual management or improved efficiency in meetings.

The third step targets improving the multi-project landscape or R&D organization, e.g., through multi-project management, development for SCM, or total costs of ownership.

Specific types of waste in R&D

- Unnecessary/ redundant features

- External quality requirements

- Redundant activities

- Stop & Go activities

- Frequent coordination

- Duplicate development

- Non-synchronized/uncoordinated activities

- Incorrect deployment

Typical results of Lean Development

- Optimization of processes

- Shortening of lead times

- Reduction of time to market

- Increase in productivity

- Increase in throughput of development projects

- Increasing internal and external customer satisfaction

- Improving transparency and communication

Christian Jagla

Partner

Phone: +49 211 63 55 89 60

Fax: +49 211 63 55 89 69

Email: info@lmx.eu

Lean Management & Digitization 2026 at Ruhr-University Bochum