Smart Factory

Use technology for waste-free processes and optimal support for people

Smart Factory

With a Smart Factory, we pursue the target of achieving waste-free processes and optimal support for people through modern production systems, new automation technologies, the use of data and its provision via assistance systems. Technology is not used as an end in itself, but to meet real existing needs and further increase your company's success.

Smart Factory Transformation starts with the structuring of processes and increases their transparency, effectiveness and efficiency.

"Bad processes remain bad processes, even if they are digitized."

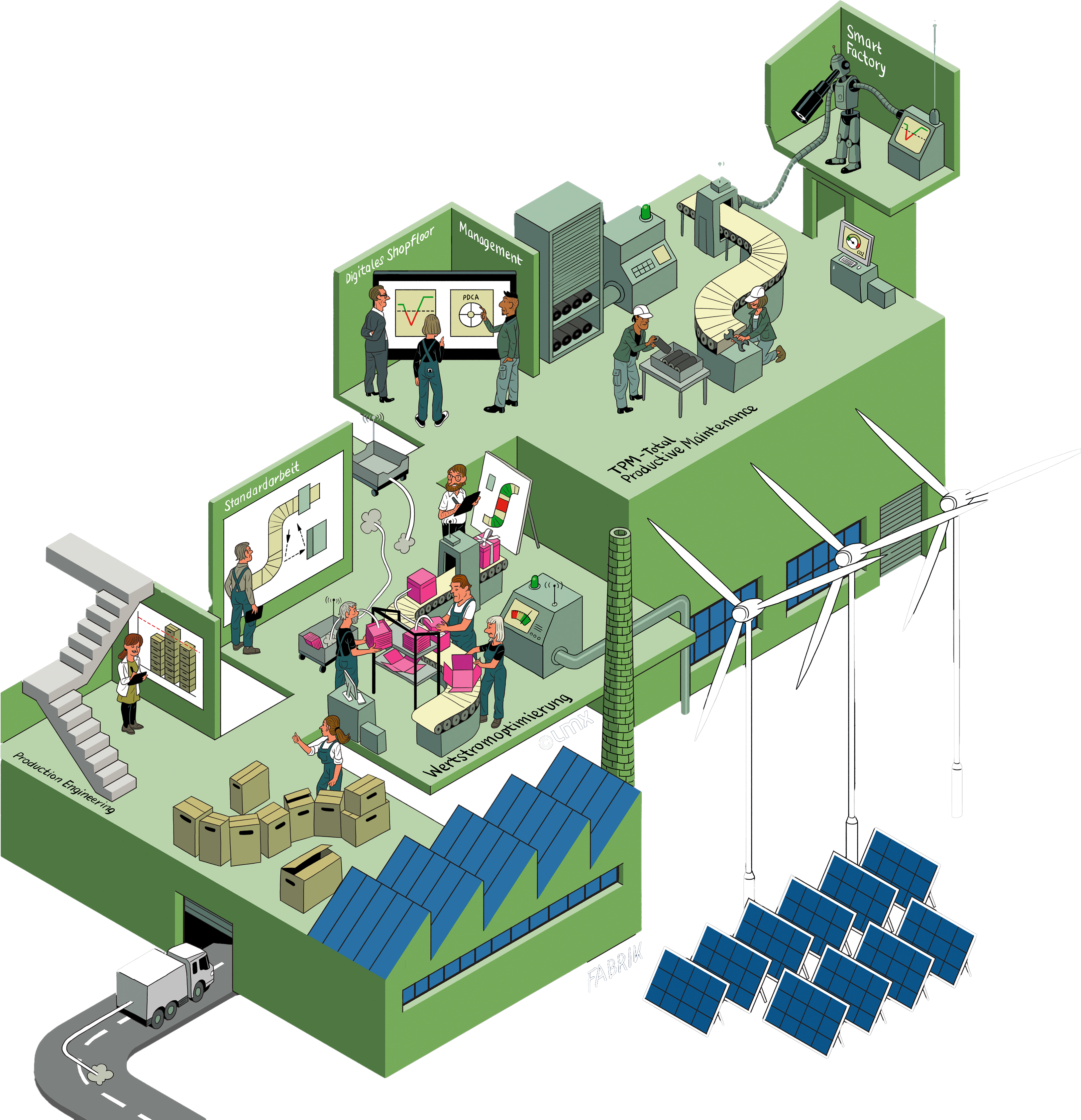

Target image Smart Factory

The technological starting points are many and varied and can be broken down into four areas: data acquisition and use, future-proof production systems, new automation and the connection of people. Each of these fields is subject to continuous innovations in the context of Industry 4.0, which enable new forms of transparency, collaboration and human-technology interaction. Let's unleash the digital potential of your production together.

Digitize your production holistically

An Industrie 4.0 transformation can be clustered into the topics of digitalization of production, digitalization of products and data-based business models. In this context, LMX focuses specifically on consulting for the digitization of production and the associated question of what the smart factory of the future can look like in concrete terms for the companies it supports.

The LMX approach combines the three core elements of a future-oriented production system: technology, organization/processes and people. Only through a coordinated interplay of these three core elements can the full value creation potential of digitalization be activated. As an implementation-oriented consultancy, we accompany you through all phases, from the identification of a common understanding of the topic, through your personalized vision and roadmap, to the utilization phase.

Christian Jagla

Partner

Alexander Schnichels

Senior Consultant

Phone: +49 211 63 55 89 60

Fax: +49 211 63 55 89 69

Email: info@lmx.eu

Lean Management & Digitization 2025 at Ruhr-University Bochum

Our solutions

We bring extensive experience in various core competencies for practice-oriented support on your way to the Smart Factory

Value Stream Management

With Value Stream Management for Smart Factories (VSM4SF) in 8 steps to the targeted optimization of the entire order-to-delivery process. This includes the information logistic types of waste as well as the survey of the "digital" quality of the value stream with the help of the digitalization KPI.

Digitales Shopfloor Management and Dashboarding

Shopfloor management is a management tool in production to make the current status of production transparent. It is visualized via team boards, where the most relevant key figures are discussed regularly (usually daily).

Smart Factory Maturity Assessment

Based on the corporate strategy and vision as well as the existing systems and technologies, we evaluate the status quo in terms of technology, organization and people and develop a target picture. A roadmap for targeted digitization is the result

Assistance systems

Together with you, we look at which assistance systems can make your production more effective. In six steps we analyze the application potential of various assistance systems for the task to be assisted and accompany the system selection up to the utilization phase.

Smart Factory Vision, Strategy and Roadmap

We work with you to develop the Smart Factory vision and derive from it the long-term strategies and a roadmap for 12-24 months with concrete measures. If required, a Smart Factory Maturity Assessment can be carried out in advance.

Automation

Using our quick check, we evaluate tasks with regard to their suitability for automation. Here, we take into account the number of pieces and product variance to determine the right degree of automation (MRC, robot, fixed automation).

Smart Maintenance

Intelligent maintenance takes into account digitization, monitoring and automated evaluation of production plants and buildings as well as the technical infrastructure of companies.

Shopfloor IT Systems

The status quo of your IT landscape consisting of data sources, middleware, databases up to data usage is analyzed and visualized. A VSM4SF can be helpful in creating transparency. We accompany you in setting up store floor management and digitization from system selection to the utilization phase.

Retrofitting

The modernization of machines and plants enables the optimization of production and the creation of added value even with older systems. With the help of retrofitting, relevant data from older systems can be collected without direct access to the machine control. We support the evaluation and accompany an implementation.

Smart Factory Trainings & Tours

We offer various open and in-house trainings on the topic of Smart Factory. Our portfolio ranges from the Awareness Session to the Smart Factory Master and can be customized to your needs. See our open training program.